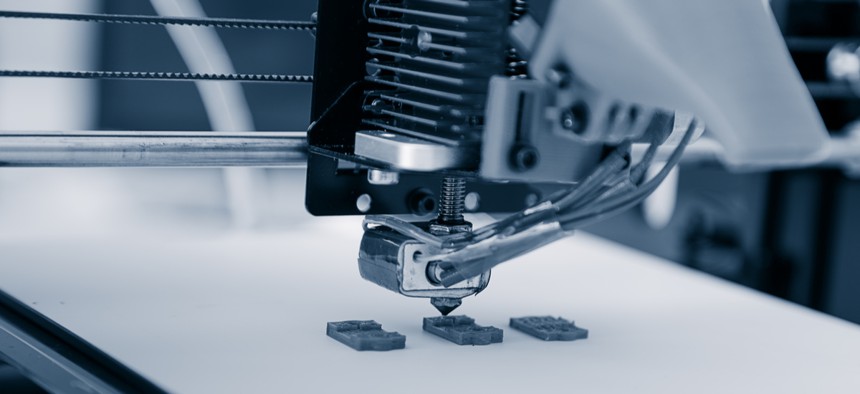

FDA, NIH, VA Partner to Accelerate 3D-Printed Protective Gear for COVID-19 Response

alex_traksel/Shutterstock

The pandemic-driven outcomes could demonstrate what strategic interagency efforts around emerging technology can catalyze in rapid timeframes.

Three federal agencies have teamed up to collectively leverage and accelerate 3D printing and other advanced manufacturing technologies in the fight against COVID-19.

The Food and Drug Administration, Veterans Affairs Department and National Institutes of Health recently signed a Memorandum of Understanding to formalize a unified effort through which they’ll solicit designs for, produce and test 3D-printed personal protective equipment and other medical supplies to support America’s response to the worldwide health emergency.

Through the work, the agencies are also engaging in a public-private partnership with the non-profit accelerator America Makes, which will act as a sort of matchmaker between the health care facilities that need the agency-approved, to-be-printed goods and manufacturing industry insiders with the capabilities to produce them.

“This initiative is rapidly evolving,” Dr. Beth Ripley, chair of the Veteran’s Health Administration's 3D Printing Advisory Committee and enterprise lead of VHA’s 3D Printing Network told Nextgov Monday. She now also serves as VA’s representative for the new MOU-driven effort.

As Ripley’s title suggests, federal agencies have been harnessing 3D printing to serve their missions in a variety of efforts over the last few years. But the global spread of the novel coronavirus ushered in new equipment shortages and growing strains on America’s medical supply chain—and subsequently introduced a fresh use for 3D printing, which can rapidly accelerate the speed between the first concept of a product, and the time it takes to produce it into reality. FDA, NIH and VA already possess the resources necessary to quickly test and share 3D-printed designs of face masks, shields and other supplies that medical personnel now need, so they likely came together to help accelerate that delivery.

Ripley shared details on the process laid out in the memorandum. It begins with NIH’s 3D Print Exchange, which is an existing tool used to share and find models that are clinically relevant and readily compatible with 3D printers. People with 3D designs of materials relevant to COVID-19 that they aim to share can submit them to NIH online. Then VA evaluates and tests the submitted designs.

“The VA 3D Printing Network prints the parts and assesses their safety and clinical efficacy in collaboration with VA’s frontline medical providers,” Ripley explained.

As part of its duties highlighted in the memorandum, VA, through its Innovation Ecosystem, also swiftly launched an external website that interested individuals and health care entities can access to submit designs, find solutions, or support the testing involved. As the designs prove to be safe and effective in VA’s assessment, FDA then participates in the review process, provides guidance and ultimately makes the final designs easily accessible online.

Finally, America Makes acts as a streamlined, solitary voice that connects those with significant 3D-printing capabilities to health care facilities with urgent needs for the supplies approved in the agencies’ process.

The partnership came together fast, moving from the original collaboration concept to actual existence in less than a week. And it’s already producing results.

"In just six days, VA tested two face shields and designed and tested one face mask,” Ripley said. “We have already made significant progress in a short time."