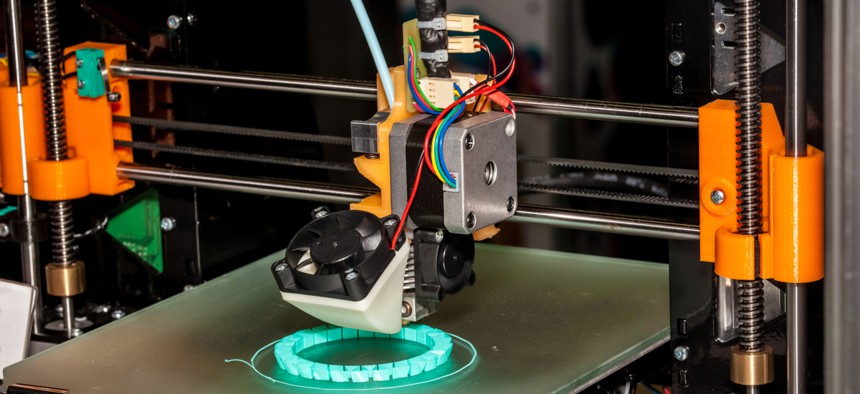

VA Looks to 3D-Printing to Improve Veteran Care

Alexander Tolstykh/Shutterstock

The agency is funding efforts to 3D-print hand braces, foot insoles, prosthetic limbs and artificial organs.

A team of doctors at the Veterans Affairs Department is pioneering new ways to use 3D-printing to plan surgeries, assist amputees and—maybe one day—build bones and organs from scratch.

Over the last three years, the Veterans Health Administration has built up a nationwide network of physicians, surgeons and researchers interested in exploring how 3D-printing can improve the lives of sick and injured veterans. The network acts as an internal hub where agency staff can share information, expertise and equipment as they each test their own 3D-printing ideas.

And its efforts are already paying off.

Today, surgeons at the Puget Sound Medical Center are using 3D-printing to rehearse operations and help patients understand their treatment options, and practitioners at other facilities are turning to the tech to build customized braces for their patients. With the group’s support, researchers are also making progress on more futuristic applications, like 3D-printing prosthetic limbs, or even artificial bones and lungs, said Beth Ripley, a VHA radiologist who today leads the agency’s 3D-Printing Advisory Committee.

“We’re really trying to spark creativity at the frontline,” Ripley told Nextgov. “Each site has complete autonomy to use the technology to explore whatever they want. Each site becomes an expert in something and disseminates all that expertise to the other sites.”

The effort began as little more than a series of casual phone calls between Ripley and physicians at three other facilities who were each experimenting with the tech. Members spent the initial conversations sharing their respective successes and failures, Ripley said, but eventually they realized they could accomplish more by organizing their efforts under the agency’s banner.

In 2016, the group received funding from the VHA Innovators Network, a program that offers grants to administration staff looking to test new health care processes and technologies. The money let them bring more 3D-printing experts into the fold and pool their equipment and materials across the network, according to Ripley.

“It's just exploded since then,” she said.

Today, the group counts members at 23 VHA facilities across the country, and it plans to add another 10 sites by the end of 2019. In January, Veterans Affairs Secretary Robert Wilkie praised the program for bringing the agency to the forefront of 3D-printing in health care.

“Through this growing virtual network, VA continues to help define how 3D-printing technology will be used broadly in medicine for the benefit of patients,” he said in a statement.

In terms of the tech, 3D-printing offers a wide variety of benefits for both veteran care and the agency’s bottom line.

Millions of veterans rely on prosthetics and orthotics provided by VHA, and 3D-printing allows physicians to customize those devices to fit each patient’s needs. Providers can build the devices on site within hours of an appointment, Ripley said, and because some 3D-printed materials are more durable than their factory-built counterparts, patients don’t need to come back as often to get new devices.

And when products do break down, doctors can quickly print and ship new ones based on the original specs, she said, saving patients a trip to a medical center that can sometimes be hours away.

Hardier products also mean VHA doesn’t need to spend as much on replacements. If the agency reduced the number of custom foot insoles it gives to diabetic patients every year from an average of three to two, each hospital would save roughly $600,000, Ripley said.

At the Puget Sound Medical Center, where Ripley works, doctors are using 3D-printing to help veterans with kidney cancer make better choices about their treatment. Based on CT scans, providers can 3D-print an exact replica of a patient’s kidney and use the model to explain the disease and possible options for surgery.

“Now all of a sudden the patient has all kinds of autonomy and ownership over his or her own body and disease to make a much more informed decision,” Ripley said. “We've had nothing but positive feedback from patients. They know what's going on, they understand the risks better and they understand what they're up against.”

The doctors themselves also use the models to prepare for surgery, which ultimately reduces the amount of time patients spend on the operating table, she said. Shorter surgeries mean less anesthesia for the patient, which could lead to speedier recovery times, she said, and considering it costs on average $81 per minute to run an operating room, VHA also stands to benefit from faster procedures.

As VHA dips its toes into more 3D-printing projects, Ripley said she anticipates the agency will see long-term improvements in patient health. Surgery recovery times could decrease as doctors spend more time prepping with 3D-printed models and hospital visits may drop as patients get medical devices better suited to their needs, she said.

But in the meantime, Ripley said the group will continue investing in both clinical applications that could benefit veterans in the months ahead and the forward-thinking research that could revolutionize the medical field years down the line.

“The sky's the limit, and I think that's really the magic of it,” Ripley said.