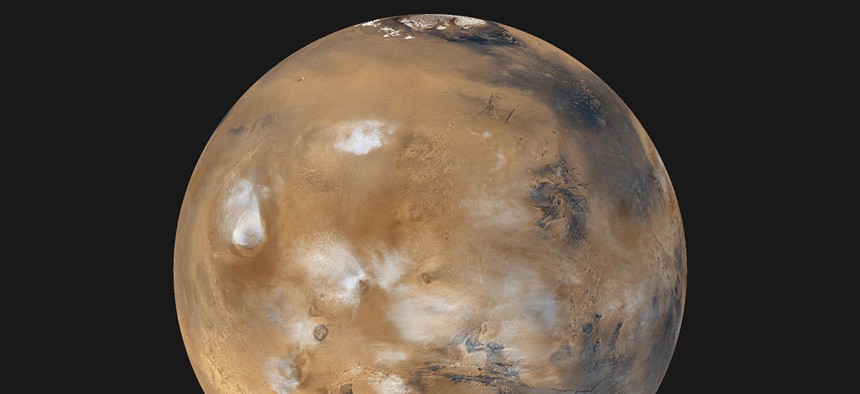

How to Build a House on Mars Using Only Materials on Mars

NASA

NASA recently rewarded a design for a 3-D-printed ice house as a promising use of Martian water deposits to make a safe, radiation-proof habitation.

Try building a house without any of the materials mere Earthlings use to build houses.

That’s the challenge facing astronauts as they move forward with colonizing Mars. They’ll either need to bring materials with them, which will be wildly expensive and generally unreliable (what if you need a spare part?), or make use of the Red Planet’s rugged, inhospitable terrain.

NASA recently rewarded a design for a 3-D-printed ice house as a promising use of Martian water deposits to make a safe, radiation-proof habitation. But water will be scarce and better used for sustaining the lives of the space settlers.

Researchers from Northwestern University have an alternative proposition: sulfur concrete. Most Earth concrete, the primary building block of modern construction, requires water mixed with cement and gravel. Sulfur, which is widely available on Mars, can take the place of water and bind the concrete together. In a study submitted to Construction and Building Materials last month and posted online, the scientists tested out different mixes of simulated Martian soil with sulfur and found the optimal concrete recipe for a sturdy Red Planet abode.

Sulfur concrete has been around for decades—it’s been used for pipelines and artificial reefs, the study notes—so the methodology was relatively straightforward. Simulated Mars soil, which has the same chemical and mineralogical properties as real Mars soil, is readily available for purchase. (Time to start that Martian terrarium you’ve always dreamed of!) So the researchers heated it up with sulfur in different ratios, then they stress-tested the concrete, both physically and through computational analysis.

Sulfur concrete made with Martian soil came out twice as strong as its Earthly counterpart, says corresponding author Gianluca Cusatis, an associate professor at Northwestern’s Department of Civil and Environmental Engineering. He thinks this is because the sulfur bonds chemically with the minerals found in Martian soil, whereas on Earth the sulfur only serves as glue for the gravel. Furthermore, since gravity on Mars is one-third what it is on Earth, the strength is effectively tripled.

This material, then, has the strength needed to construct a shelter. But it also solidifies in an hour or less. Even fast-setting concrete takes 24 to 48 hours, Cusatis says, and regular concrete needs up to 28 days to set. That makes sulfur concrete much more attractive for 3-D printing, which is likely to play a role in construction on other planets. Probably most significant, though, is the farm-to-table aspect.

“All the materials are in situ, so there is no need to bring them, which makes the construction also sustainable,” Cusatis says. “You might need a solar panel to use solar energy to melt the sulfur, but that’s about it.”

The substance can also be melted down and recast, so it’s reusable. The main drawback, Cusatis notes, is that it’s not very resistant to high temperatures; if a sulfur concrete building catches fire, the heat could melt the material. Future studies will need to look at how to engineer the concrete to have a higher thermal resistance. The researchers would also like to better understand how the crucial chemical reactions work, so they can optimize the strength and efficiency of the manufacturing process.

The endgame looks promising. NASA could send an advance team of robots to print structures of locally sourced sulfur concrete, so when humans arrive, they could install an airtight membrane inside the protected enclave. With that complete, they can kick back with a guilt-free glass of Martian spring water.

NEXT STORY: What Color Lightsaber Would Use the Most Energy?