The Space Suit You Could Be Wearing In a Few Years Is Being Designed in a Small Workshop in Brooklyn

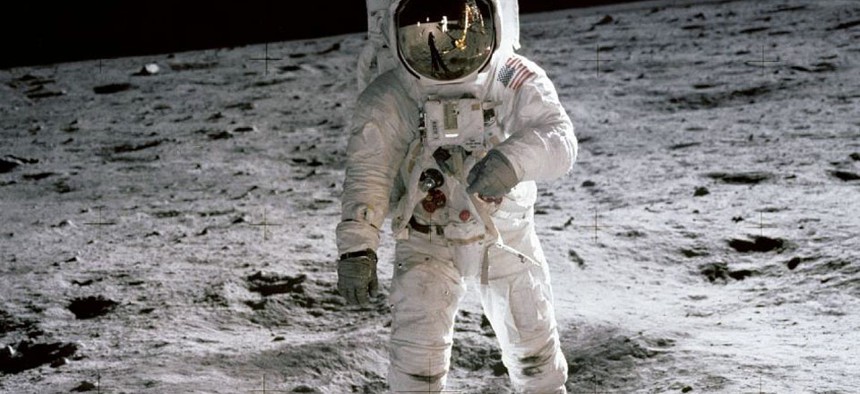

Apollo 11 mission commander Neil Armstrong took this iconic photograph of Buzz Aldrin walking on the moon. NASA

Fashion and space flight have a long history together.

While you can always find next season’s most cutting-edge looks in Manhattan’s Garment District, the most futuristic outerwear in New York City wasn’t on the runways during the recent Fashion Week.

Rather, it’s to be found in a small studio in Brooklyn, where an émigré Russian engineer and a US-born artist are making the ultimate in bespoke couture—the space suit—into a fast-fashion product, one-size-fits-all.

Their company is called—what else?—Final Frontier Design. But before we join them in their East River atelier, we should discuss why the problem of what to wear in space has become so pressing.

We are, perhaps, on the cusp of a significant increase in the number of humans in space. The International Space Station has maintained an average population of about six since it was first inhabited in 2000, with fluctuations during crew change-overs or when China’s space station, Tiangong-1, is occupied. But in 2017, if all goes to plan, SpaceX and Boeing will become the first private companies to put people in space, and the US, China and India are all mooting more manned missions in orbit and beyond. The dream of Martian colonists and asteroid miners has never seemed so close to reality.

“I can pretty much assure you that there are going to be people bringing people with money to space, and they’ll have to wear something,” says Nicholas de Monchaux, an architect who wrote a history of the Apollo space suit.

That something won’t typically be the outfit you might remember from the film Gravity or those grainy videos of Apollo astronauts cavorting on the moon—white, boxy, radiation-resistant, armored against micro-meteoroids and equipped with a life-support system. Such extra-vehicular activity (EVA) suits will be left to professionals working outside the protective confines of a spacecraft.

Rather, the average space traveler will need something to wear inside in case of an emergency when getting up and down again in a rocket or during tricky maneuvers like docking. These are called IVA—intra-vehicular activity—suits, or simply pressure suits. As space travel moves farther from its roots in military technology and scientific exploration and becomes more commercial, passengers will require a pressure suit that’s more effective, comfortable—and, heck, stylish.

The good news is that fashion and space flight have a long history together. The first space suits for the Apollo program were built by Playtex, the underwear maker, and the subsidiary it spun off for the purpose is still a NASA contractor. David Clark, the company behind NASA’s distinctive orange “pumpkin suit,” among many others, was also originally a textile-knitting firm. And Final Frontier’s staff have backgrounds in making Broadway musical and circus costumes.

“Space travel is part of the relationship between fashion and adventure that goes back to the first balloon flights of the 18th century, which had an enormous influence on women’s fashion at the time,” de Monchaux says. “Public access to space is just beginning, and so this notion of dressing for space that was so often science fiction is going to become a reality.”

A tire in the shape of a person

First, let’s dispel a common myth. If you find yourself in a free-fall more than 12 miles (19 km) above the earth, your blood won’t boil. But your tears will—if, that is, they don’t freeze first.

At that altitude, the low atmospheric pressure makes water boil at human body temperature. Your blood, confined and somewhat pressurized by your circulatory system, will stay liquid. But the lack of oxygen, temperatures as low as -60°F (-51°C), and the expansion of trapped gases in your body will soon kill you.

Late 19th-century aeronauts breaking altitude records in gas balloons were the first to start passing out from lack of oxygen. Above 10,000 feet (3,000 meters), the vital gas becomes sparse enough to cause noticeable effects. By 43,000 ft, the more pressing challenge becomes getting carbon dioxide out of the lungs—”Imagine blowing a five-inch plug of water out of your snorkel in the swimming pool each time you exhaled, and doing that for a couple of hours or more,” in the words of a former US Air Force officer quoted in NASA’s official history of altitude suits. The solution is to find some way to recreate the pressure of earth’s atmosphere, so there’s enough oxygen to breathe and enough pressure on the torso to exhale easily.

Aviation pioneer Wiley Post in his pressure suit. (He lost his eye during a brief stint working in an oil field, and used the settlement to buy his first airplane.)(NASA)

Wiley Post, a pioneering US pilot, is credited with developing the first pressure suit. In 1932, after designing his own autopilot and flying around the world solo in just under eight days, he became convinced the only way to beat his record was to go higher. In the thinner air of the stratosphere, he reckoned that powerful tail winds would give him greater speed; indeed, Post found something whose existence had been postulated but not yet confirmed—the jet stream. At the time, few pilots flew above 20,000 ft. Post wanted to fly a cross-country aerial race at a then unheard-of 30,000 ft—higher than Mount Everest.

Working with the B.F. Goodrich company, Post developed an inflatable rubber suit that he could wear while operating his airplane—“a tire in the shape of man,” de Monchaux says. Though inflating the suit forced him to walk at a stoop, Post eventually spent about 30 hours in the stratosphere, reaching altitudes as high as 50,000 ft and setting speed records thought impossible for his single-engine plane.

Just two years after his first pressure-suit flight, Post and a passenger, the humorist Will Rogers, died in a plane crash, after the engine in a borrowed aircraft stopped suddenly. I imagine this as the 1930s equivalent of Felix Baumgartner and Jon Stewart dying together in a flying accident.

But Post had helped identify the key challenge of building a human-shaped pressure environment. When something is inflated, it wants to be round. Humans, however, are not spherical, and even more problematically, they have all kinds of fiddly joints and bends. Creating a pressurized suit that someone can actually do something in still presents problems today.

A human fist in a rubber glove

I was experiencing climate-control problems of my own as I tried to find Final Frontier Design’s studio in January. The staff works from a warehouse in the Brooklyn Navy Yard on New York’s East River, and I was struggling to find the right building on my phone’s GPS in below-freezing temperatures with one cold-stiffened, un-gloved hand. Fitting, then, that FFD came together over gloves—space-suit gloves.

The glove is considered the most challenging space-suit component to design. It is the astronaut’s main interface with the world, but it is often uncomfortable—something I experienced firsthand in FFD’s glove-testing vacuum chamber. The electric pump gradually depressurized the box, and the glove around my hand stiffened. Subtle wrist motions I hadn’t registered before were suddenly missed as my fingers scrabbled around, fighting the glove as I attempted to pick up small metal objects. No wonder astronauts complained about lost fingernails and skin abrasions.

Nikolai Moiseev, left, and Ted Southern, the co-founders of Final Frontier Design, in their Brooklyn studio.(Quartz/Tim Fernholz)

FFD’s founders, Nikolai Moiseev and Ted Southern, met in 2007 as rivals in a public NASA competition to design a better glove. At the time, Southern was earning a master of fine arts degree in sculpture at Brooklyn’s Pratt Institute of Design. His work also included theatrical costumes; Cirque du Soleil remains a client of the company. Moiseev, meanwhile, had spent two decades working on space suits at Zvezda, Russia’s leading space suit company. He saw the contest as a chance to leave his home country, where bureaucracy and funding problems stifled his creativity, and find new opportunities in the commercial space sector of the US.

The first year, they were competitors, working on different teams; neither won. But in 2009, they teamed up to create a glove that outperformed NASA’s model.

Perhaps as a child, you inflated a rubber glove into the rough approximation of a balloon bird. Imagine now that you have to blow up—pressurize—that glove, but the fingers must remain independent and mobile, capable of grasping, and the palm must remain curved slightly inward, so it can hold things. Traditionally, space-suit gloves have solved this problem by having two layers, a pressurized bladder inside and a restraint layer outside. But the friction between them makes it harder for astronauts to move their hands.

The winner.(FFD)

Moiseev and Southern’s winning design was a glove with a single layer—they were able to use an air-tight material to create the combined effect of an air bladder wrapped in fabric, significantly reducing friction. With the modest prize money and new contacts, they were able to incorporate FFD and get Moiseev US residency. They began winning small research and development contracts for gloves, sleeves and other components. By 2010, the company had completed its prototype of a fully-functioning IVA suit.

Its current suits, which include built-in helmets, are also single-layer, relying on high-tech fabrics heat-welded at the seams. The pressure they generate while inflated is about one-third that of the earth’s atmosphere at sea level, allowing you to survive for several hours in the event of decompression. They also protect you when rocket acceleration generates forces equal to three times earth’s gravity, thanks to special bladders that inflate around your legs during take-off and re-entry. The suit includes an oxygen system, temperature controls, utility pockets, a built-in sunshade, integrated communications systems and, yes, a “biomedical port” for medical diagnostics and human waste.

Experience has led space programs to conclude that a pressure suit is worth the weight, cost and discomfort. Soviet astronauts flew without pressure suits—“they wanted to project an image of this being a ride on a bus,” de Monchaux says—but when an oxygen valve failed on a Soyuz craft returning to earth in 1971, it depressurized 100 miles above the ground. The recovery crew found the three cosmonauts onboard dead from asphyxiation. Now, all Soyuz crew members wear suits when they fly.

US astronauts on the space shuttle likewise went into space in “shirtsleeve comfort,” in the words of one NASA hand-out, until the commission formed to investigate the Challenger explosion in 1986 demanded more robust efforts to protect them. Pressure suits became mandatory, and the iconic “pumpkin suit”—or the Advanced Crew Escape Suit (ACES)—was developed.

The crew of the Space Shuttle Discovery sport their pumpkin suits in 1998, including 77 year-old John Glenn, third from right, a former Mercury astronaut making his second trip to space.(NASA)

A pressure suit probably won’t protect you if your vehicle violently explodes, so they wouldn’t have helped the seven-person Challengercrew, and they didn’t save the crew of Columbia, which broke apart during its return to earth in 2003. However, a pressure suit likely saved the life of the pilot in a high-altitude Air Force surveillance plane in 1966, when it broke apart during maneuvers at a similar altitude and speed to the space shuttle.

On the International Space Station itself, most of the time is spent in shirtsleeves. Yet pressure suits still come in handy in times of danger—such as the potential ammonia leak that recently led some of the astronauts to briefly evacuate their compartment, until a sensor failure was blamed. You don’t wear an oxygen mask or life vest on a jetliner, but you still want to know they’re there if you need them.

Height couture

As Southern and Moiseev show me around their studio—glass cabinets full of gloves, racks of space suits, a life-size model of the suit worn by Laika the Soviet space dog—one of their partners, Kari Love, is diligently using modeling software to create a schematic of a wrist clasp that will eventually be 3D-printed out of titanium. (The company expects that 3D printing will allow astronauts to generate their own replacement parts while in orbit.) Love’s title is chief pattern maker and fabricator, and her background is in costumes—she built the Spiderman costume for the ill-fated Broadway musical.

“Broadway show costumes are used in a high-performance environment and built in small hand-manufacturing runs,” Love wrote in an e-mail. “Their construction can address concerns of durability, technological integration, safety, cost effectiveness and human factors—all traits in common with spacesuits.”

The space industry has long looked to clothing designers for help. “Big industrial companies tried to make space suits and didn’t do it very well,” de Monchaux told me. “But David Clark in the 40s and Playtex in the 60s and 70s, the companies that did design very well for the body… had expertise in the complex, uncomfortable women’s underwear of the era. The Apollo space suit manufacturing operation and the latest generation of EVA suits was literally spun out of a company making rubber underwear.”

That has led to some memorable culture clashes. In the mid-1970s, when testing precursors to the space shuttle, NASA asked David Clark to provide pressure suits for the pilots. One, Bill Dana, complained that the white boots that came with his suit weren’t masculine enough, saying “I might as well wear pink boots.” According to the NASA history, the next suit to be delivered came with black boots—and a pair of pink ones, with “adhesive flower decals.” Dana, a good sport, modeled the boots in two ensuing test flights.

Bill Dana sports his pink boots.(NASA)

The high-pressure future of fashion

Like many space-focused entrepreneurs, FFD thinks it can disrupt incumbent government contractors—or at least compete successfully—thanks to cheap new technology, methods and materials. Last December, the company signed a research agreement to develop a new IVA suit for NASA.

Currently, NASA is planning on using the latest iteration of the ACES pumpkin suit when it flies manned missions in its Orion spacecraft, beginning in 2018. It is modifying the suit to function outside the space capsule as well, for a mission to an asteroid the agency hopes to launch sometime after 2020. Here, astronauts get some practice in the suit during an underwater training session:

Southern thinks his suit might be a better candidate for that mission, because it’s more flexible and operates at higher pressurization than the ACES suit, reducing the risk of altitude sickness. It is also 14 lbs (6 kg) lighter, saving 100 lbs of weight for a full crew of seven astronauts—which may not sound like much, but remember that the cost of a rocket launch is measured in thousands of dollars per pound. FFD’s suits also cost $80,000 each, far less than the $250,000 spent on ACES suits.

And the market is expanding. Both Boeing and SpaceX intend to fly humans into space in 2017, and it is not yet clear what they will wear. SpaceX is reportedly developing its own suit, though FFD has had several meetings with the company. Boeing remains mum, but Southern says he expects it to use one of the established contractors. Virgin Galactic is not planning to use pressure suits aboard its space plane, which will make only short flights above the atmosphere, but more serious missions—whether that’s bringing tourists to floating habitats in orbit or on the moon, as Bigelow Aerospace is mulling; mining asteroids, per Planetary Resources; or sending an expedition to Mars, a là NASA and SpaceX—will all involve long periods in space and tricky maneuvers in addition to launch and re-entry.

Even so, Southern and Moiseev concede that the market for space suits may not pick up fast enough for them to build a truly humming business beyond small contracts from NASA and a few other high-altitude entrepreneurs. But they hope to spin a sideline in terrestrial clothes out of their latest generation of space-suit designs.

For example, they see an opening in wearable tech, where they could use the experience garnered while creating the most extreme wearable technology in existence. They already market their “comm caps”—skull caps with built in radio gear used by astronauts—as headsets for gamers. Southern also showed me the prototype of a belt he is developing. Fitted with tiny, vibrating motors connected with electronic threads, it could relay directions to a pedestrian by feel, so she wouldn’t have to hold a mobile phone. I wished I’d had one when I was trying to find his offices.