Siemens Is Building a Swarm of Robot Spiders to 3-D Print Objects Together

Siemens Corporate Technology

Current technology won’t allow us to make anything larger than the printing machines themselves. That could soon change.

3-D printing is still in its infancy, but it’s starting to show signs that it might revolutionize the way we manufacture products. That said, current technology won’t allow us to make anything larger than the printing machines themselves. Some smart people have suggested that we should look to nature to see how it builds things—specifically, spiders, and the way they can swarm together to build massive nests for themselves.

Siemens, the German engineering and telecommunications company, has taken this concept to heart. A team of researchers at its Princeton, New Jersey, laboratory are creating autonomous spider-like robots that can work together to 3-D-print structures on command.

While Siemens isn’t known for its robotics research, Livio Dalloro, the head of the company’s “Product Design, Simulation & Modeling Research” group in Princeton, said in an interview that the company views the bots as a “moonshot.” It hopes to entice researchers from across its hundreds of global offices to develop applications for the robots and create new products.

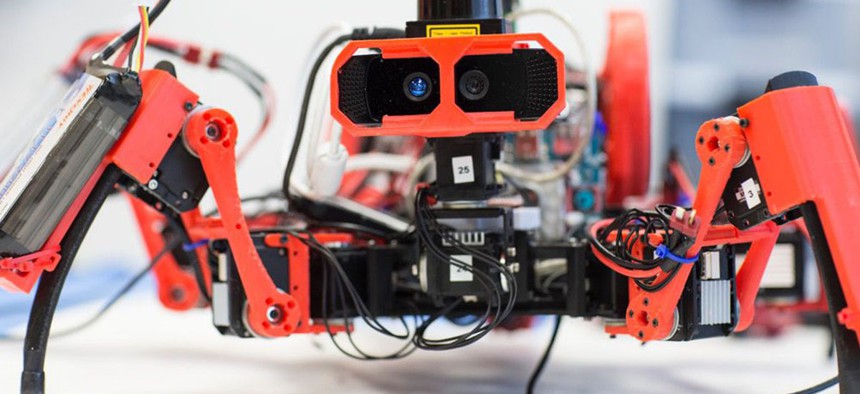

The eight-legged robots have a myriad of sensors that can perceive the world around them. They use a combination of a depth-perception camera (similar to Microsoft’s Kinect system) and an infrared laser scanner to “see” the world.

Dalloro said the team at the lab have been working for a few years to design and simulate the software to figure out how the robots would move, and how they would work together, so that if one bot was working on building one section of an object, his teammate wouldn’t get in his way.

The team first concentrated on getting one robot to print something on a flat surface on its own, then print a small plastic object a few inches tall, using essentially the same plastic printing technology found in many consumer 3-D printers. Now, the team is working on using multiple robots to simultaneously build the same objects. Once the robots are able to work together, the researchers will focus on getting them to build larger objects.

Dalloro said the lab has two fully functioning robots, and a third that it’s using for testing. He said the lab plans to build at least three more soon as it scales up the bots’ ability to build collaboratively.

“The idea is really to make these flexible autonomous, communicating, general purpose machines,” he said.

The team is also working on building with different materials. Currently, robots can only print out plastics—at about the same speeds that a traditional 3-D printer would—but Dalloro said they’re researching other materials, such as concrete.

In theory in the future, an engineer could upload a design file to a group of robots and ask them to work together to figure out how to build it. There are now 3-D printers for electric circuits, for steel, for carbon fiber, and even for human tissues: Swarms of bots like could one day build us the next iPhone, the next Burj Khalifa, or perhaps even your next liver. They could also help build structures that traditional manufacturing processes can’t.

Jordan Brandt, then a futurist at Autodesk, the design software company, said last year that the future of design will mimic the way things are structured in nature, which has a few millennia of evolutionary design on the average human engineer. That concept will likely come about because robots, paired with algorithmic software, can build in all dimensions far faster than a human could.

“Things end up looking very biological,” Brandt said.

Siemens’ research is not tied to any specific commercial goal, Dalloro said, but it could help the company figure out new products to pursue. Dalloro compared it to the original “moonshot”—humanity’s first trip to the moon—which gave rise to modern computer systems and many other products.

“We are interested in those side effects,” Dalloro said. Besides, “it’s just cool to work on things like this.”