Watch New 3-D Printing Technique Create Intricate Objects From a Pool of Goo

Carbon3D

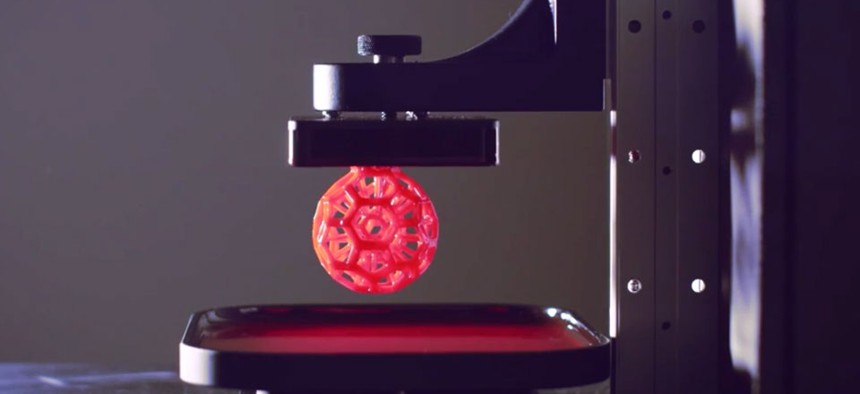

Most existing consumer-grade 3D printers print in layers that fuse together to make the final object. Carbon3D takes a different approach.

3D printing is stuck in a bit of a rut. There are companies trying to push the technology beyond the trinket market, but many of the existing printers are slow, jam often, and don’t always make perfect copies. One new printer introduced at the TED conference may have the answer.

Most existing consumer-grade 3D printers print in layers that fuse together to make the final object. Carbon3D takes a different approach, by pulling a seamless object out of a pool of photosensitive resin:

Carbon3D CEO and co-founder Joseph DeSimone, a chemical engineering professor at the University of North Carolina with more than 150 patents to his name, said he and his team were inspired by the T-1000 robot from Terminator 2, and what they created seems right out of science fiction.

Here’s how it actually works: A light shines through the pool of resin, which causes the resin to harden. Oxygen, on the other hand, causes the resin to liquify. Using them both in combination, a light source can be intricately controlled like a three-dimensional film projector, so only certain parts of the resin are pinpointed and hardened as the object is pulled out of the goo.

DeSimone told TED attendees that his technique can make objects that can’t be manufactured by existing 3D printing methods, and more quickly to boot. He made one object onstage in under seven minutes during his talk.

Carbon3D’s printing process is between 25 and 100 times faster than traditional 3D printers, DeSimone said. His printers also create smoother products—without the frayed edges and rough surfaces found in other 3D printed products—which DeSimone said would lead to stronger 3D-printed materials.