The Industrialization of Space

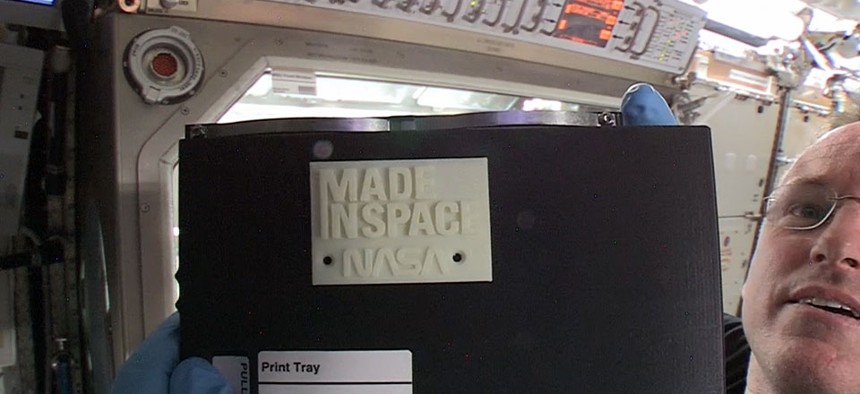

International Space Station Commander Barry “Butch” Wilmore holds up the first object made in space with additive manufacturing or 3-D printing. NASA

This week, NASA marked a milestone: the first object manufactured outside of Earth.

We may talk about "space tourism" as a specialized form of space travel; even the most cutting-edge space exploration, though, is disconcertingly similar to the basic experience of Earth-bound voyaging. You pack your bags, trying your best to plan for every circumstance that might arise while you're away, and then you're stuck with what you've brought. In space's case, the suitcases in question may be spacecraft and the tools required may be slightly more complex than voltage converters and travel-size shampoos ... but the idea's the same: If you'll need something on your trip to space, you have to bring it with you.

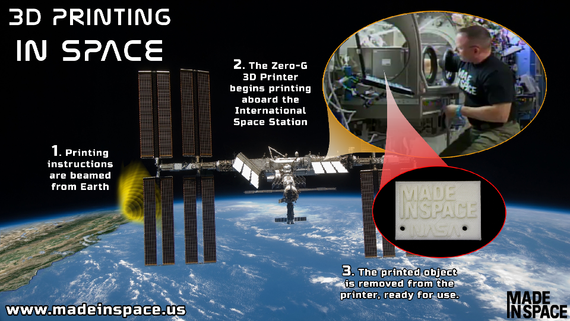

That basic paradigm, though, is changing. This week, NASA announced a breakthrough: For the first time, humans have 3-D-printed an object to be used in space exploration from space itself . The item in question was appropriately meta: a faceplate for the 3-D printer that was recently delivered to the International Space Station , the laboratory that orbits some 240 miles from Earth.

"It's not only the first part printed in space, it's really the first object truly manufactured off planet Earth," Aaron Kemmer, the CEO of Made in Space, which built the printer for NASA, told NBC News . "Where there was not an object before, we essentially 'teleported' an object by sending the bits and having it made on the printer. It's a big milestone, not only for NASA and Made In Space, but for humanity as a whole."

That may be hyperbole, but it's also true. Space's suitcase paradigm has meant that using objects outside of Earth has required huge amounts of energy—and, with them, expense. That's the reason why, for example, space food so often comes in dehydrated forms (water adds weight to a spacecraft's payload) and why astronauts living in space drink their own recycled urine (same reason).Using 3-D printers, however, engineers on Earth can simply email or upload designs to spacecraft that can, in turn, print out the objects. Spacecraft can become industrialized.

As Forbes 's Leo King put it , "The list of conceivable applications is as vast as science-backed imagination will allow."

That list includes construction. "For exploration missions," Niki Werkheiser, project manager for the ISS's 3-D Printer, told King , "we will be able to use larger 3-D printers to construct the structures we will need to live and operate." Those include not just landing pads and radiation protection, but also habitats. It's conceivable, for example, that Martian regolith, or soil, could be used as a building material in printers.

In the nearer future, though, a working 3-D printer in space means leaner, more efficient space missions. Instead of designing objects built to withstand the forces that come with a launch into space, away from Earth’s gravity, engineers can simply design objects as they're needed on the Station. This, Werkheiser told King, "opens up a design space we’ve never had before."

Spare parts? Nano-satellites? All the items we need to explore and understand the world beyond Earth? These can all be affected by the mini-factory now working on the ISS. If humanity's next step in space is making the transition from visitors to settlers , we'll need to manufacture the tools we need not on Earth, but from space itself. Additive manufacturing will help us to do that.

NEXT STORY: Infographic: NASA's Great Effect on Tech